OVERVIEW

Most industrial equipment, electronic devices, and consumer electronics are equipped with controllers. These controllers continuously monitor and make decisions based upon the firmware settings and sensor data to control the state of the system. In case of a system malfunction, these controllers also reflect the problem with preset error codes that help to address the issue. Usually, technicians have to go to the field for troubleshooting and service upgrades. This in turn incurs cost in terms of time and money.

Typically, IoT solutions are aimed to crudely connect devices (things) to the internet, using external sensors and actuators to overlay the system rather than integrating to it. Thus, they are unable to read these in-built sensors and redundantly introduce new sensors to monitor the system. Moreover, during device malfunctions, most IoT solutions are unable to accurately identify or mitigate the issues. In effect, they are rendered onlookers, unable to become active participants.

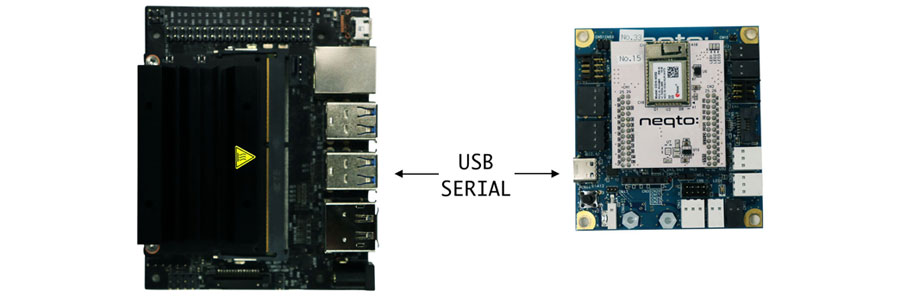

On the other hand, neqto: interfaces directly with the controller of the device while ensuring minimal invasion and forming a symbiotic relationship. This allows neqto: to utilize the existing components of the system. Also, since neqto: actually talks to the host controller, it can delegate commands and change the operation of the system. This also paves the way to read the exact error from the device and furthermore be capable to solve them remotely. With neqto:, debugging and repair during system failures can be monitored and resolved with minimal effort, saving precious time and money.

MACHINE DRIVER

To harness the full potential of this integration, neqto: comes with an abundance of features. One of them is Machine Driver.

Machine Driver gives neqto: users the ability to modify the firmware settings of their devices remotely. With this feature customers can deploy fixes in the form of firmware updates over the air at the click of a button. This will save crucial time, and eliminate any logistical costs during failure.

For other devices that have traditionally had their firmware set on production, neqto: opens up new avenues and serves as a way for manufacturers to provide their customers software support, adding the flexibility to upgrade their device software after the device has left the factory.

USECASES

Some examples of the products/areas that will benefit from integrating neqto: in their cores are

- Refrigerators - Monitor/control fridge temperature and humidity. Crucial in the food industry where any fault can result in quality deterioration.

- HVAC Systems - Monitor/control building/room temperature and humidity. Resolve failures that conventionally require tedious repairs.

- On-board diagnostics in vehicles - Monitor/control automobile health and performance. Give maintenance predictions based on collected data.

- PLCs used in industries - Monitor/control machine operation. Fix faults and keep log reports of production metrics.

In the next blog, we'll give a simple example of how to get started with Machine Driver.