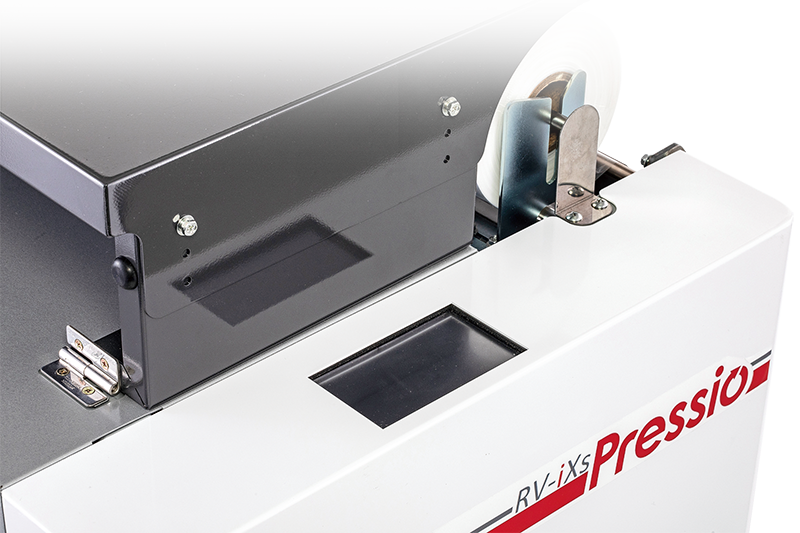

From Hokkaido to Kyushu, Pressio Inc. provides equipment such as collating and wrapping machines to newspaper dealers across Japan. Since its establishment, it has been working side by side with the newspaper industry for nearly 50 years. Now, Pressio is actively developing new products and services, utilizing its manufacturing technology and maintenance capabilities. Their new product, "Automatic Wrapping Machine RV-iX/RV-iXs," uses NEQTO to create the first machine of its type to be equipped with IoT functions. By detecting machine malfunctions before they occur, this product is expected to reduce labor costs for maintenance management by 20% and convert that time into sales activities.

"’Performance’, ‘speed’, and ‘cost’ were the deciding factors when choosing NEQTO. Using NEQTO to enable IoT functions lets us remotely monitor the status of our customer’s equipment and detect errors, leading to more efficient maintenance operations and improved customer satisfaction."

Mr. Inoue

Development, Manufacturing Department, Pressio Inc.

Implementing IoT During New Product Development

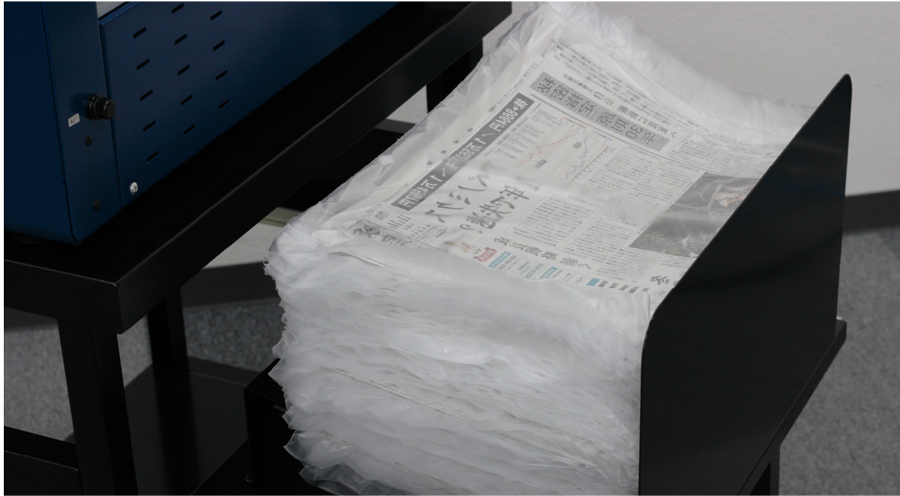

Focusing on the sales of equipment like collating and wrapping machines, Pressio is actively creating new markets through new and value-added services that fulfil the needs of future operations and equipment used by newspaper dealers. The subject of this IoT initiative is their newspaper wrapping machine, a device for wrapping newspapers in plastic on rainy days that is provided to newspaper distributors nationwide.

Until recently, Pressio’s maintenance support consisted of two variations: Planned maintenance, and corrective maintenance whereby support would rush to locations for inspection and repair following calls regarding malfunctions. However, in the latter case it often took a long time to restore function because they could not identify the location of the failure within the machine until they arrived at the site for inspection, and replacement parts could not be prepared in advance. In addition, the cause of malfunction can be difficult to predict due to various factors, such as installation and climatic conditions. They felt they were not meeting their customers’ expectations, so to improve maintenance efficiency they decided to implement IoT functionality (a communication module) into their machines. “As the development of our first new model in five years was underway, we found out that combining the Salesforce business system with NEQTO would immediately improve our maintenance efficiency, and as the project progressed we quickly decided to incorporate IoT functionality.”

said Mr. Inoue, General Manager of Development at Pressio’s Manufacturing Department.

Choosing NEQTO for its Small Size, Quick Delivery, and Low Cost

Mr. Inoue’s development department is responsible for all aspects of product development, from the equipment used by distributors, to new ideas for services, what kind of products to make, costs, and mass production. Pressio started considering IoT for product development in 2019, and after investigating several services, decided on NEQTO. Mr. Inoue explains that their decision to go with NEQTO was the result of selecting the optimal solution when compared to other potential partners.

Since the decision to add IoT functionality was made in the middle of their product’s development, most of the product specifications had already been decided. This meant that space for the installation of new additions was limited. This is part of what led to Pressio’s three main considerations when searching for a solution: small size, quick delivery, and low cost. In particular, it was necessary to have the IoT module as small as possible within the limited available space,

so that it would leave room for circulation and not heat up when the wrapping machine was using high-temperature heat to cut the plastic film.

“Our top priorities for the project were module size, overall cost, and delivery time. NEQTO has multiple options for wireless communication, but as we didn't want to worry about continual communication costs or run up the customer’s final cost, we went with the Wi-Fi model. We ended up accelerating our development plans because by finding NEQTO, we were confident that we could release our new service and meet the performance and requirements we were aiming to achieve.” (Mr. Inoue)

All future manufacturing of the company's new IoT-enabled newspaper wrapping machine are set to be equipped with NEQTO.

Reduction in Maintenance Time Creates Expected 20% Increase in Operating Efficiency

Starting with pre-sale in June 2020 and full-scale mass production in August, Pressio’s sales of both new installations and replacements have been strong and are expected to exceed their annual target. The two main results of NEQTO’s implementation into their system are the reduction of maintenance time and the improvement of sales performance.

In the past, it was not always possible to know the location of a malfunction until physically going to inspect it, and no one knew about the problem until the user themselves contacted them. In some cases, the equipment was still in use even though problems were occurring. In addition, sales representatives are also responsible for maintenance, which meant that they had to spend extra time visiting customers and fixing malfunctions. This was putting a strain on their sales activities. The visualization of operating data has now enabled them to identify the point of failure before visiting the site, which enables responders to prepare parts in advance and identify the potential cause of failure at the site more quickly.

Specifically, sales representatives are now able to immediately inform customers of even minor errors, giving them greater peace of mind. “In the event of a malfunction we can now identify the location of the failure in advance, which allows us to complete the inspection, repair and part replacement all at once. This not only saves time during the repair, but also reduces potential machine downtime as well.” (Mr. Inoue)

With the ability to determine if a product is malfunctioning and identify replacement parts in advance, Pressio expects to reduce the amount of time spent by sales staff on maintenance work, allowing them to focus on their core sales work.

"By increasing the sales efficiency of our nationwide sales staff by 20%, we expect to see a significant increase in results" says Mr. Inoue.

Next Goal: Use NEQTO in Other New Products to Leverage Data

Currently, Pressio is planning development to incorporate NEQTO’s IoT function into its main product, the collating machine. With NEQTO as an “IoT hub,” they hope to create a new market by aiming to do what other companies have not been able to.

“Since we also ship our products overseas we need our services to be available globally, and we also need to be able to provide for different environments. NEQTO’s wide applicability allows us to have this flexibility, for example with the LTE model for environments without Wi-Fi access. Furthermore, we would also like to utilize data from the product in the development of our future projects so that we can predict customer needs and further improve maintenance efficiency.” (Mr. Inoue)

For future products, Pressio is considering integrating the NEQTO standard MCU (microcontroller) and Wi-Fi module directly into their product board design, which is expected to reduce the overall product size and cost.

“Although we were able to meet our goals this time by prioritizing development speed, there are still some areas where we can improve, such as further cost reductions. We hope that JIG-SAW will continue to work with us in reducing hardware costs by reducing the number of components.” (Mr. Inoue)

| Customer Profile: Pressio Inc. | |

|---|---|

| • | President and CEO: Otani Takashi |

| • | Number of Employees: 159 (As of June, 2019) |

| • | Business Description: Manufacturing, sale, and repair of electrical machinery/equipment |

| Results & Further Developments | |

|---|---|

| • | Providing added value as a premium service by linking machine operation status with their system in real time |

| • | Expected 20% increase in operation efficiency achieved through predictive maintenance, identifying and anticipating operational failures |

| • | Released an industry-first IoT product by embedding NEQTO Engine into their equipment |